The design of the die casting mold cooling system has a significant impact on the efficiency of the flushing process. Properly designed cooling channels allow for the even distribution of cooling water throughout the mold, ensuring that all areas are adequately cooled. If the design is flawed or the channels are not properly positioned, it can lead to uneven cooling and hot spots in the mold, making it more challenging to flush out any debris or contaminants effectively.

When the cooling channels in a die casting mold are not properly flushed, several common issues can arise. These include the buildup of scale, rust, or other contaminants that can restrict the flow of cooling water, leading to inefficient cooling of the mold. Additionally, inadequate flushing can result in blockages in the channels, causing uneven cooling and potentially affecting the quality of the cast parts produced.

Tompkins County poised for manufacturing boom with Menlo Micro and Micron investments “Menlo Micro announced a significant investment of over $50 million to establish a fabrication facility in Lansing, near Ithaca, New York, signaling a major boost for the local manufacturing workforce.” Read more Plug Power wins $75 million grant from DOE “The Latham hydrogen … NYS Manufacturing and Tech News 3.11.24 Read More »

Posted by on 2024-03-15

We continue our blog series on the great work of our New York State assets in Advanced Materials across the state. This week, we feature the work of Rensselaer Polytechnic Institute (RPI) in Troy, NY, and their work on next generation building technology with an aim to decarbonize the built environment. This includes working with … Advanced Materials Strengths and Assets in NYS: Focus on Rensselaer Polytechnic Institute Read More »

Posted by on 2024-02-28

Embark on an enlightening exploration of New York’s economic transformation with special guest Alyson Slack from MRB Group, as we uncover the past and present of the state’s manufacturing sector. Together with FuzeHub’s Steve Melito we chart the course from a robust production history to a burgeoning service-oriented economy, all while acknowledging manufacturing’s lasting contributions … Podcast: Building Better Economies Read More »

Posted by on 2024-03-18

New $25M beauty manufacturing and innovation hub for Black- and women-owned businesses coming to Brooklyn Navy Yard “The Brooklyn Navy Yard is set to be home to a new $25 million state-of-the-art manufacturing, incubator, and accelerator facility focused on helping Black- and women-owned health and beauty businesses launch and grow in New York City.” Read … NYS Manufacturing and Tech News 3.4.24 Read More »

Posted by on 2024-03-08

In our third feature in our New York State Assets blog series on Advanced Materials, we focus on the groundbreaking work at the University at Buffalo. Their Department of Materials Design and Innovation focuses on accelerating lab discoveries into practical engineering applications. They are pioneering new approaches in material science education and research, leveraging technologies … Advanced Materials Strengths and Assets in NYS: Focus on University at Buffalo Read More »

Posted by on 2024-03-06

The temperature of the cooling water can significantly impact the effectiveness of the mold cooling system flush. Water that is too hot may not effectively remove contaminants or debris from the cooling channels, while water that is too cold may not have enough cleaning power. It is essential to maintain the optimal temperature range for the flushing process to ensure thorough cleaning and prevent any issues with mold cooling efficiency.

Additives play a crucial role in the flushing process of a die casting mold cooling system. These additives are often used to enhance the cleaning power of the flushing solution, helping to break down stubborn contaminants and prevent the buildup of scale or rust in the cooling channels. By incorporating additives into the flushing process, manufacturers can ensure that their mold cooling systems remain clean and efficient.

Recommended maintenance procedures for ensuring the longevity of a die casting mold cooling system include regular inspection and cleaning of the cooling channels, monitoring the temperature and flow rate of the cooling water, and using additives as needed to prevent scale or rust buildup. Additionally, it is essential to follow the manufacturer's guidelines for maintenance and flushing to ensure optimal performance and extend the lifespan of the mold cooling system.

The flow rate of the flushing solution can have a significant impact on the cleaning of the cooling channels in a die casting mold. A higher flow rate can help to dislodge and remove contaminants more effectively, ensuring a thorough flush of the system. However, it is essential to balance the flow rate to prevent damage to the mold or cooling channels, as excessive pressure can cause wear and tear over time.

There are specific types of flushing solutions that are more effective for cleaning die casting mold cooling systems. These solutions often contain corrosion inhibitors, surfactants, and other additives designed to break down contaminants and prevent scale or rust buildup. Manufacturers may choose a flushing solution based on the specific needs of their mold cooling system and the types of contaminants they typically encounter. It is essential to select a high-quality flushing solution to ensure the cleanliness and efficiency of the cooling channels in the die casting mold.

Yes, the company offers specialized repairs for industrial air handling units, including services such as troubleshooting, maintenance, replacement of components, and upgrades for HVAC systems in commercial and industrial settings. Our team of experienced technicians is trained to work on a variety of air handling units, including rooftop units, air handlers, exhaust fans, and ventilation systems. We use advanced diagnostic tools and techniques to identify and address issues with efficiency, airflow, filtration, and temperature control. Additionally, we provide customized solutions to optimize the performance and energy efficiency of industrial air handling units, ensuring a comfortable and healthy indoor environment for employees and customers.

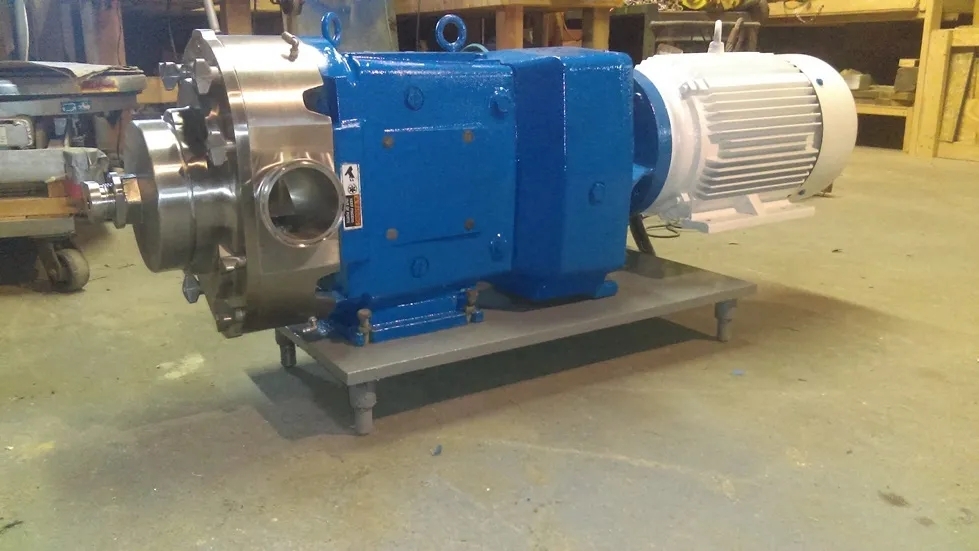

Industrial pump maintenance services typically include routine inspections, lubrication, alignment checks, vibration analysis, and performance testing. These services help ensure the pumps are operating efficiently and effectively, reducing the risk of breakdowns and costly repairs. Additionally, maintenance may involve replacing worn or damaged parts, such as seals, bearings, and impellers, to prolong the lifespan of the pump. Regular maintenance also includes monitoring fluid levels, pressure, and temperature to identify any potential issues before they escalate. Overall, industrial pump maintenance is crucial for maximizing productivity and minimizing downtime in industrial settings.

The company specializes in repairing various models of die casting machinery, including but not limited to Toshiba, Buhler, Frech, Italpresse, and Idra machines. Our team of experienced technicians is trained to work on a wide range of die casting equipment, ensuring that each repair is completed efficiently and effectively. Whether it's troubleshooting electrical issues, replacing worn-out parts, or performing routine maintenance, our experts have the knowledge and skills to handle any repair job. With a focus on precision and quality, the company is dedicated to providing top-notch service for all die casting machinery models.

When it comes to handling repairs for industrial reactors, the process typically involves a team of trained technicians who specialize in reactor maintenance and troubleshooting. These professionals are equipped with the necessary tools and equipment to diagnose and address any issues that may arise, such as leaks, cracks, or malfunctions. They follow strict safety protocols and procedures to ensure the repair work is completed efficiently and effectively. Additionally, regular inspections and preventive maintenance are key components of keeping industrial reactors in optimal working condition. By staying proactive and addressing any issues promptly, companies can minimize downtime and maximize the lifespan of their reactors.