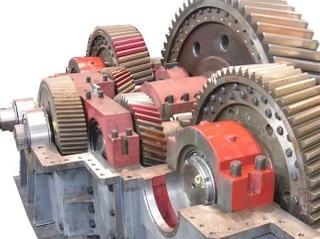

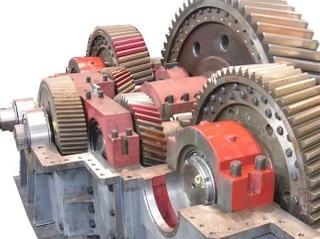

When it comes to lubricating industrial mixer shaft bearings, the best options typically include high-quality grease or oil specifically designed for heavy-duty industrial applications. Grease is often preferred for its ability to stay in place and provide long-lasting lubrication, while oil can offer better heat dissipation in certain high-speed applications. It is important to choose a lubricant that is compatible with the bearing material and operating conditions to ensure optimal performance and longevity.

To ensure optimal performance of industrial mixer shaft bearings, they should be lubricated at regular intervals as recommended by the manufacturer or based on the operating conditions. In general, industrial mixer shaft bearings should be lubricated on a regular maintenance schedule, which could range from monthly to quarterly depending on the intensity of use. Regular lubrication helps prevent wear and tear, reduces friction, and extends the lifespan of the bearings.

Tompkins County poised for manufacturing boom with Menlo Micro and Micron investments “Menlo Micro announced a significant investment of over $50 million to establish a fabrication facility in Lansing, near Ithaca, New York, signaling a major boost for the local manufacturing workforce.” Read more Plug Power wins $75 million grant from DOE “The Latham hydrogen … NYS Manufacturing and Tech News 3.11.24 Read More »

Posted by on 2024-03-15

We continue our blog series on the great work of our New York State assets in Advanced Materials across the state. This week, we feature the work of Rensselaer Polytechnic Institute (RPI) in Troy, NY, and their work on next generation building technology with an aim to decarbonize the built environment. This includes working with … Advanced Materials Strengths and Assets in NYS: Focus on Rensselaer Polytechnic Institute Read More »

Posted by on 2024-02-28

Embark on an enlightening exploration of New York’s economic transformation with special guest Alyson Slack from MRB Group, as we uncover the past and present of the state’s manufacturing sector. Together with FuzeHub’s Steve Melito we chart the course from a robust production history to a burgeoning service-oriented economy, all while acknowledging manufacturing’s lasting contributions … Podcast: Building Better Economies Read More »

Posted by on 2024-03-18

New $25M beauty manufacturing and innovation hub for Black- and women-owned businesses coming to Brooklyn Navy Yard “The Brooklyn Navy Yard is set to be home to a new $25 million state-of-the-art manufacturing, incubator, and accelerator facility focused on helping Black- and women-owned health and beauty businesses launch and grow in New York City.” Read … NYS Manufacturing and Tech News 3.4.24 Read More »

Posted by on 2024-03-08

In our third feature in our New York State Assets blog series on Advanced Materials, we focus on the groundbreaking work at the University at Buffalo. Their Department of Materials Design and Innovation focuses on accelerating lab discoveries into practical engineering applications. They are pioneering new approaches in material science education and research, leveraging technologies … Advanced Materials Strengths and Assets in NYS: Focus on University at Buffalo Read More »

Posted by on 2024-03-06

Using the wrong type of lubricant for industrial mixer shaft bearings can have serious consequences on their performance and longevity. For example, using a lubricant that is not compatible with the bearing material can lead to accelerated wear, increased friction, and potential overheating. Additionally, using a lubricant with the wrong viscosity or temperature range can result in poor lubrication, reduced efficiency, and premature failure of the bearings.

Temperature requirements for lubricating industrial mixer shaft bearings can vary depending on the operating conditions and the type of lubricant being used. In general, it is important to consider the temperature range in which the bearings will be operating to ensure that the lubricant remains effective and does not break down or evaporate prematurely. Some high-speed applications may require lubricants with higher temperature resistance to withstand the heat generated during operation.

Signs that indicate industrial mixer shaft bearings need to be re-lubricated include increased noise or vibration during operation, higher operating temperatures, reduced efficiency, and visible signs of wear on the bearings. If the bearings are not properly lubricated, they may experience increased friction, which can lead to overheating, premature wear, and ultimately, failure. Regular monitoring of the bearings and their performance can help identify when re-lubrication is necessary.

Over-lubrication can indeed cause damage to industrial mixer shaft bearings by creating excess pressure within the bearing housing, leading to increased friction, overheating, and potential leakage. When bearings are over-lubricated, the excess lubricant can also attract contaminants such as dust and dirt, which can further accelerate wear and reduce the efficiency of the bearings. It is important to follow manufacturer recommendations for lubrication amounts to prevent over-lubrication.

In high-speed mixing applications, special considerations must be taken into account when lubricating industrial mixer shaft bearings. These applications typically generate higher temperatures and increased friction, requiring lubricants with superior heat resistance and anti-wear properties. It is crucial to select a lubricant that can withstand the demanding conditions of high-speed mixing to ensure optimal performance and longevity of the bearings. Regular monitoring and maintenance are also essential to prevent premature wear and failure in high-speed applications.

When it comes to handling repairs for industrial ovens used in manufacturing, the process typically involves conducting a thorough inspection to identify the root cause of the issue. This may include checking components such as heating elements, thermocouples, control panels, and ventilation systems. Once the problem is diagnosed, skilled technicians with expertise in industrial oven repair will perform the necessary repairs or replacements. This could involve tasks such as recalibrating temperature settings, replacing faulty parts, or repairing electrical connections. Additionally, regular maintenance schedules may be implemented to prevent future breakdowns and ensure optimal performance of the industrial ovens. Overall, a proactive approach to repairs and maintenance is crucial in maintaining the efficiency and reliability of industrial ovens in manufacturing settings.

Yes, our company specializes in providing comprehensive repair services for industrial incinerators. Our team of highly trained technicians has extensive experience in handling a wide range of issues related to incinerator maintenance and repair, including combustion chamber repairs, refractory lining replacements, burner adjustments, and emission control system troubleshooting. We use advanced diagnostic tools and cutting-edge technology to ensure that your incinerator is restored to optimal performance levels. Additionally, we offer preventive maintenance programs to help prevent future breakdowns and maximize the lifespan of your equipment. Trust our experts to deliver top-notch repair solutions for your industrial incinerator needs.

The company specializes in repairing a wide range of industrial pumps from various brands, including but not limited to Grundfos, Goulds, Sulzer, KSB, and Flowserve. Our team of experienced technicians is well-versed in servicing centrifugal pumps, diaphragm pumps, submersible pumps, and many other types commonly used in industrial applications. With expertise in troubleshooting, maintenance, and repair of industrial pumps, the company ensures that each pump is restored to optimal performance to minimize downtime and maximize efficiency for our clients.

When it comes to handling repairs for CNC plasma cutting machines, the technician must first diagnose the issue by conducting a thorough inspection of the machine's components such as the torch, power supply, and control system. They may need to use specialized tools like multimeters or oscilloscopes to pinpoint the exact source of the problem. Once the issue is identified, the technician will then proceed to repair or replace the faulty parts, ensuring that the machine is back up and running efficiently. It is crucial for the technician to have a deep understanding of CNC technology, plasma cutting processes, and machine maintenance in order to effectively troubleshoot and repair any issues that may arise. Regular maintenance and calibration of the machine are also essential to prevent future breakdowns and ensure optimal performance.

Yes, the company offers maintenance contracts for ongoing equipment servicing to ensure the continued functionality and performance of the machinery. These contracts include regular inspections, repairs, and replacements of parts as needed to prevent breakdowns and prolong the lifespan of the equipment. By signing up for a maintenance contract, customers can rest assured that their equipment will be well taken care of by trained technicians who specialize in servicing specific types of machinery. Additionally, these contracts may also include emergency services and priority scheduling for any unexpected issues that may arise. Overall, maintenance contracts provide peace of mind and help to optimize the efficiency and reliability of the equipment.

An experienced technician with expertise in industrial machinery maintenance can effectively troubleshoot electrical issues in manufacturing equipment. By utilizing specialized tools and diagnostic equipment, they can identify and resolve problems such as faulty wiring, malfunctioning components, or power supply issues. This requires a deep understanding of electrical systems, circuitry, and control panels, as well as knowledge of safety protocols and regulations. The technician may also need to interpret schematics, blueprints, and technical manuals to pinpoint the root cause of the issue and implement the necessary repairs. Additionally, they must be able to work efficiently to minimize downtime and ensure the smooth operation of the manufacturing process.