The blast wheel in a shot blasting machine should be inspected for wear and tear on a regular basis, ideally every 500 hours of operation. This preventive maintenance schedule helps to identify any signs of damage or deterioration early on, allowing for timely repairs or replacements to be made before more significant issues arise.

Common signs of damage or malfunction in a blast wheel that require maintenance include unusual noises during operation, decreased blasting efficiency, uneven abrasive distribution, and visible wear on the blades or impeller. If any of these symptoms are observed, it is essential to stop the machine immediately and conduct a thorough inspection to determine the root cause of the problem.

Tompkins County poised for manufacturing boom with Menlo Micro and Micron investments “Menlo Micro announced a significant investment of over $50 million to establish a fabrication facility in Lansing, near Ithaca, New York, signaling a major boost for the local manufacturing workforce.” Read more Plug Power wins $75 million grant from DOE “The Latham hydrogen … NYS Manufacturing and Tech News 3.11.24 Read More »

Posted by on 2024-03-15

We continue our blog series on the great work of our New York State assets in Advanced Materials across the state. This week, we feature the work of Rensselaer Polytechnic Institute (RPI) in Troy, NY, and their work on next generation building technology with an aim to decarbonize the built environment. This includes working with … Advanced Materials Strengths and Assets in NYS: Focus on Rensselaer Polytechnic Institute Read More »

Posted by on 2024-02-28

Embark on an enlightening exploration of New York’s economic transformation with special guest Alyson Slack from MRB Group, as we uncover the past and present of the state’s manufacturing sector. Together with FuzeHub’s Steve Melito we chart the course from a robust production history to a burgeoning service-oriented economy, all while acknowledging manufacturing’s lasting contributions … Podcast: Building Better Economies Read More »

Posted by on 2024-03-18

New $25M beauty manufacturing and innovation hub for Black- and women-owned businesses coming to Brooklyn Navy Yard “The Brooklyn Navy Yard is set to be home to a new $25 million state-of-the-art manufacturing, incubator, and accelerator facility focused on helping Black- and women-owned health and beauty businesses launch and grow in New York City.” Read … NYS Manufacturing and Tech News 3.4.24 Read More »

Posted by on 2024-03-08

In our third feature in our New York State Assets blog series on Advanced Materials, we focus on the groundbreaking work at the University at Buffalo. Their Department of Materials Design and Innovation focuses on accelerating lab discoveries into practical engineering applications. They are pioneering new approaches in material science education and research, leveraging technologies … Advanced Materials Strengths and Assets in NYS: Focus on University at Buffalo Read More »

Posted by on 2024-03-06

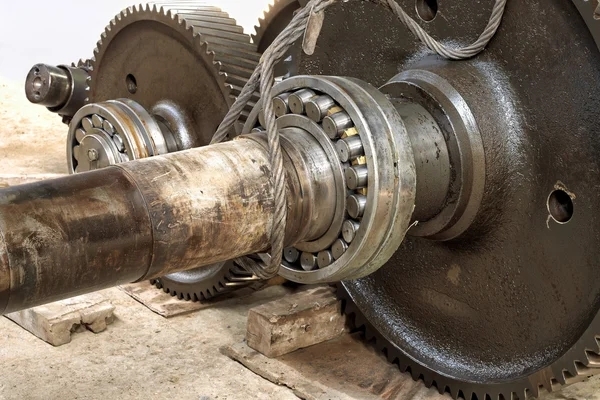

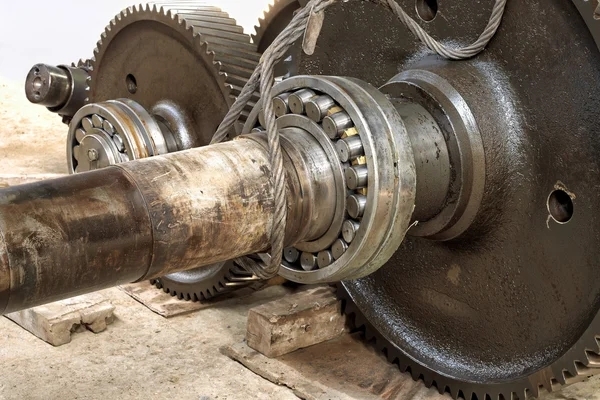

Regular lubrication of the blast wheel components is necessary to ensure smooth operation and prevent premature wear. A high-quality, industrial-grade lubricant specifically designed for use in shot blasting machines should be applied to the bearings, seals, and other moving parts according to the manufacturer's recommendations. This helps to reduce friction, heat, and wear, extending the lifespan of the blast wheel.

To clean and maintain the blast wheel for optimal performance, it is recommended to first shut down the machine and disconnect power to ensure safety. Then, remove any abrasive buildup, dust, or debris from the wheel housing and blades using compressed air or a brush. Inspect the components for signs of wear or damage, and replace any worn-out parts as needed. Finally, reassemble the blast wheel and test it to ensure proper functioning before resuming operation.

When performing maintenance on the blast wheel of a shot blasting machine, specific safety precautions must be taken to prevent accidents or injuries. This includes wearing appropriate personal protective equipment such as gloves, safety glasses, and hearing protection. Additionally, following lockout/tagout procedures, working in well-ventilated areas, and avoiding contact with moving parts are essential safety measures to minimize risks during maintenance tasks.

To determine if the blast wheel blades need to be replaced, inspect them for signs of wear, chipping, or deformation. If the blades are worn down beyond a certain point or show visible damage, it is recommended to replace them to maintain optimal blasting performance. The process for replacing blast wheel blades involves carefully removing the old blades, installing new ones according to the manufacturer's instructions, and ensuring proper alignment and balance for smooth operation.

Specialized tools and equipment may be required for maintaining the blast wheel of a shot blasting machine, such as blade removal tools, bearing pullers, and alignment gauges. These tools can be obtained from industrial equipment suppliers, shot blasting machine manufacturers, or online retailers specializing in abrasive blasting accessories. It is essential to use the correct tools and follow proper procedures to ensure safe and effective maintenance of the blast wheel.

To ensure accuracy in equipment repairs, the technicians at the repair facility follow a strict protocol that includes conducting thorough diagnostic tests, utilizing specialized tools and equipment, referencing technical manuals and schematics, and staying up-to-date on the latest industry standards and best practices. They also undergo regular training and certification programs to enhance their skills and knowledge in repairing a wide range of equipment types, such as electronic devices, machinery, and appliances. Additionally, the technicians document all repair processes and outcomes meticulously to track the progress and ensure quality control. By adhering to these measures, the repair facility can guarantee accurate and reliable repairs for their customers.

The company provides comprehensive on-site repair services for a wide range of heavy machinery, including excavators, bulldozers, cranes, and loaders. Our team of experienced technicians is equipped to handle repairs, maintenance, and troubleshooting for various types of heavy equipment. With specialized knowledge in hydraulic systems, engines, and electrical components, our technicians can efficiently diagnose and address any issues that may arise. Additionally, we offer preventative maintenance services to ensure that your machinery operates at peak performance and minimizes downtime. Whether it's a minor repair or a major overhaul, our on-site repair services are designed to keep your heavy machinery running smoothly and efficiently.

Yes, our company provides specialized repair services for industrial shredders. Our team of experienced technicians is trained to handle a wide range of issues that may arise with industrial shredders, including motor malfunctions, blade replacements, jammed feed mechanisms, and electrical problems. We use advanced diagnostic tools and high-quality replacement parts to ensure that your industrial shredder is restored to optimal working condition. Additionally, we offer preventative maintenance services to help prolong the lifespan of your equipment and minimize the risk of future breakdowns. Trust our experts to provide efficient and reliable repairs for your industrial shredder.

Yes, the technicians at the CNC machining center repair facility are highly skilled in repairing specific models of CNC machining centers. They have expertise in working with various brands and models, including Haas, Mazak, Okuma, and Fanuc. These technicians are trained to diagnose and troubleshoot issues with precision, ensuring that the CNC machining centers are restored to optimal working condition. Additionally, they have access to specialized tools and equipment to efficiently repair any mechanical, electrical, or software-related problems that may arise. Whether it's a spindle issue, axis alignment problem, or control system malfunction, the technicians at the CNC machining center repair facility have the knowledge and experience to address the specific needs of each model.

Industrial chiller maintenance services typically include tasks such as regular inspections, cleaning of condenser coils, checking refrigerant levels, monitoring for leaks, adjusting controls, calibrating sensors, lubricating moving parts, replacing worn-out components, testing safety features, and conducting performance evaluations. Additionally, preventive maintenance measures may involve analyzing system efficiency, optimizing energy consumption, implementing predictive maintenance strategies, and ensuring compliance with industry regulations. Proper maintenance of industrial chillers is crucial to prevent breakdowns, extend equipment lifespan, improve operational efficiency, and minimize downtime. Specialized technicians with expertise in refrigeration systems are often employed to perform these maintenance tasks to ensure optimal performance and reliability of industrial chillers.

Specialized robotics used in manufacturing processes require a high level of expertise to service effectively. Technicians must be well-versed in programming, maintenance, troubleshooting, and repair of industrial robots, automated machinery, and robotic systems. They need to have a deep understanding of mechatronics, control systems, sensors, actuators, and other related technologies. Additionally, familiarity with PLCs, HMIs, SCADA systems, and industrial communication protocols is essential for diagnosing and resolving issues with these advanced robotics. Continuous training and staying up-to-date with the latest advancements in robotics technology are crucial for providing top-notch service to manufacturers relying on these specialized machines.