Hydraulic guillotine shear blades should be sharpened regularly to maintain optimal cutting performance. It is recommended to sharpen the blades after every 10,000 to 15,000 cuts, depending on the material being cut and the intensity of use. Regular sharpening helps to ensure clean and precise cuts, reduces wear on the machine, and extends the lifespan of the blades.

When sharpening hydraulic guillotine shear blades, it is crucial to use the recommended techniques to ensure precision and longevity. The blades should be sharpened using a professional sharpening machine or by a skilled technician. The sharpening process should involve removing any nicks or burrs, maintaining the correct angle and bevel, and ensuring that both blades are sharpened evenly to avoid uneven cutting.

Tompkins County poised for manufacturing boom with Menlo Micro and Micron investments “Menlo Micro announced a significant investment of over $50 million to establish a fabrication facility in Lansing, near Ithaca, New York, signaling a major boost for the local manufacturing workforce.” Read more Plug Power wins $75 million grant from DOE “The Latham hydrogen … NYS Manufacturing and Tech News 3.11.24 Read More »

Posted by on 2024-03-15

We continue our blog series on the great work of our New York State assets in Advanced Materials across the state. This week, we feature the work of Rensselaer Polytechnic Institute (RPI) in Troy, NY, and their work on next generation building technology with an aim to decarbonize the built environment. This includes working with … Advanced Materials Strengths and Assets in NYS: Focus on Rensselaer Polytechnic Institute Read More »

Posted by on 2024-02-28

Embark on an enlightening exploration of New York’s economic transformation with special guest Alyson Slack from MRB Group, as we uncover the past and present of the state’s manufacturing sector. Together with FuzeHub’s Steve Melito we chart the course from a robust production history to a burgeoning service-oriented economy, all while acknowledging manufacturing’s lasting contributions … Podcast: Building Better Economies Read More »

Posted by on 2024-03-18

New $25M beauty manufacturing and innovation hub for Black- and women-owned businesses coming to Brooklyn Navy Yard “The Brooklyn Navy Yard is set to be home to a new $25 million state-of-the-art manufacturing, incubator, and accelerator facility focused on helping Black- and women-owned health and beauty businesses launch and grow in New York City.” Read … NYS Manufacturing and Tech News 3.4.24 Read More »

Posted by on 2024-03-08

In our third feature in our New York State Assets blog series on Advanced Materials, we focus on the groundbreaking work at the University at Buffalo. Their Department of Materials Design and Innovation focuses on accelerating lab discoveries into practical engineering applications. They are pioneering new approaches in material science education and research, leveraging technologies … Advanced Materials Strengths and Assets in NYS: Focus on University at Buffalo Read More »

Posted by on 2024-03-06

Specific angles and bevels need to be maintained during the sharpening process for hydraulic guillotine shear blades. The blades typically have a specific angle at which they are sharpened, usually around 25 to 30 degrees. It is important to maintain this angle to ensure that the blades cut smoothly and efficiently. Additionally, the bevel of the blades should be consistent to prevent any issues with cutting accuracy.

Signs that indicate hydraulic guillotine shear blades need to be sharpened include decreased cutting efficiency, rough edges on the cut material, or an increase in the amount of force required to make a cut. If the blades are not cutting cleanly or are leaving jagged edges, it is likely time to sharpen them. Regular inspection of the blades for wear and tear can help prevent any issues with cutting quality.

It is possible to sharpen hydraulic guillotine shear blades in-house, but it is recommended to seek professional sharpening services for the best results. Professional sharpening services have the expertise and specialized equipment needed to sharpen the blades accurately and efficiently. While in-house sharpening can be done, it may not always produce the same level of precision and longevity as professional sharpening.

When handling hydraulic guillotine shear blades during the sharpening process, special considerations and precautions should be taken to ensure safety and effectiveness. It is important to wear appropriate protective gear, such as gloves and eye protection, to prevent injuries. Additionally, the blades should be handled carefully to avoid any damage or accidents during the sharpening process.

Neglecting to sharpen hydraulic guillotine shear blades regularly can have several consequences, including damage to the machine and decreased product quality. Dull blades can put additional strain on the machine, leading to increased wear and potential breakdowns. In addition, dull blades can result in rough cuts, jagged edges, and decreased precision, affecting the overall quality of the cut materials. Regular sharpening is essential to maintain the efficiency and longevity of hydraulic guillotine shear blades.

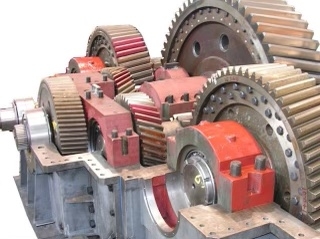

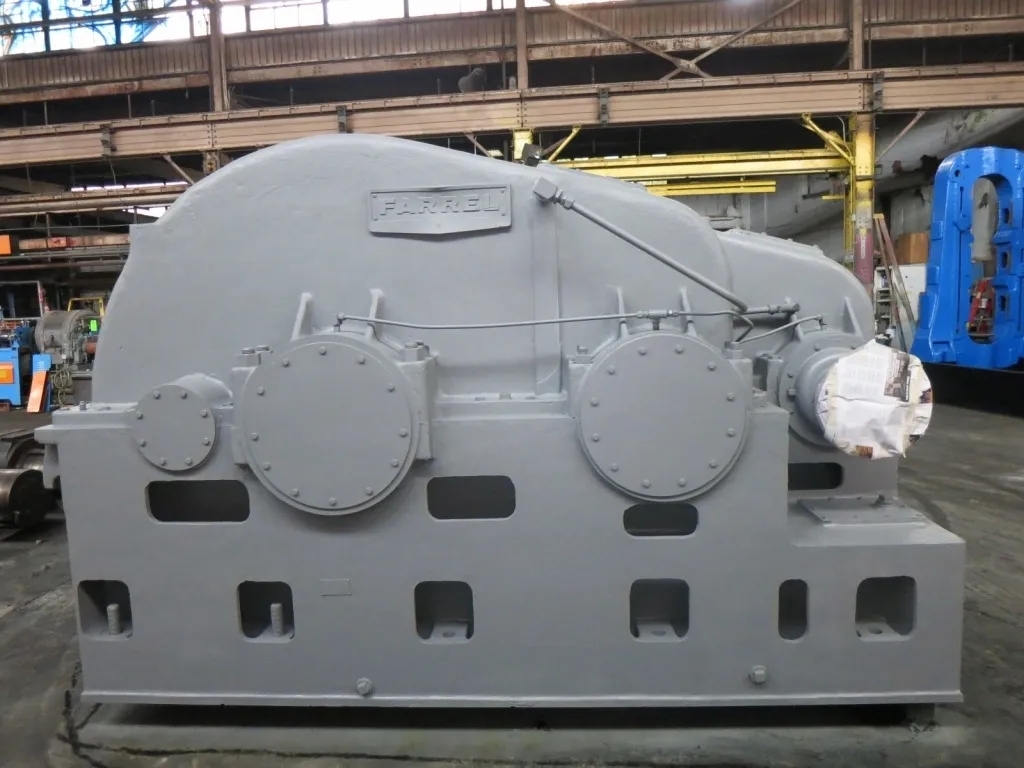

The process for refurbishing outdated manufacturing equipment typically involves a thorough assessment of the machinery's current condition, identifying any faulty components or outdated technology that need to be replaced or upgraded. This may include disassembling the equipment, cleaning and repairing any damaged parts, and installing new components to improve performance and efficiency. Additionally, the refurbishment process may involve updating software, recalibrating sensors, and conducting rigorous testing to ensure the equipment meets industry standards and regulations. Once the refurbishment is complete, the equipment is reassembled, tested, and certified for use in manufacturing operations. This comprehensive approach to refurbishment helps extend the lifespan of outdated equipment, reduce downtime, and improve overall productivity in manufacturing facilities.

The company specializes in providing comprehensive repairs for heat exchangers commonly utilized in manufacturing processes. These specialized services include diagnosing and addressing issues such as corrosion, fouling, leaks, and pressure drops in heat exchangers. The team of skilled technicians is trained to work on a variety of heat exchanger types, including shell and tube, plate and frame, and air-cooled heat exchangers. By utilizing advanced techniques and tools, the company can efficiently restore heat exchangers to optimal performance levels, ensuring smooth operation within manufacturing facilities. Additionally, the company offers preventative maintenance programs to prolong the lifespan of heat exchangers and minimize downtime.

Industrial chiller maintenance services typically include tasks such as regular inspections, cleaning of condenser coils, checking refrigerant levels, monitoring for leaks, adjusting controls, calibrating sensors, lubricating moving parts, replacing worn-out components, testing safety features, and conducting performance evaluations. Additionally, preventive maintenance measures may involve analyzing system efficiency, optimizing energy consumption, implementing predictive maintenance strategies, and ensuring compliance with industry regulations. Proper maintenance of industrial chillers is crucial to prevent breakdowns, extend equipment lifespan, improve operational efficiency, and minimize downtime. Specialized technicians with expertise in refrigeration systems are often employed to perform these maintenance tasks to ensure optimal performance and reliability of industrial chillers.

Professional CNC lathe repair technicians have the expertise to service a wide range of specific models, including but not limited to Mazak, Haas, Okuma, Mori Seiki, and Doosan lathes. These technicians are trained to diagnose and troubleshoot issues with spindle motors, ball screws, tool changers, and other components of CNC lathes. They are skilled in performing preventative maintenance, replacing worn parts, and calibrating machines to ensure optimal performance. By staying up-to-date on the latest technologies and techniques in CNC lathe repair, these technicians can effectively address any issues that may arise with specific models of CNC lathes.