Various types of manufacturing equipment require repair services, including CNC machines, injection molding machines, conveyor systems, robotic arms, and packaging equipment. These machines are essential for the production process and any malfunction can lead to costly downtime and decreased productivity.

In today's fast-paced manufacturing environment, ensuring optimal performance of equipment is paramount. Maintaining peak efficiency through timely repairs can significantly enhance productivity and minimize downtime. To learn more about Manufacturing Equipment Repair Services and how they can streamline operations and prolong equipment lifespan, visit: https://precisiongearrepair.com

Efficient repair services not only address immediate issues but also contribute to long-term cost savings and operational reliability, enabling businesses to stay competitive in the dynamic manufacturing landscape.

Manufacturing equipment should undergo regular maintenance to prevent breakdowns and ensure optimal performance. The frequency of maintenance depends on the type of equipment, its usage, and the manufacturer's recommendations. Typically, equipment should be inspected and serviced at least once a year, with more frequent checks for high-demand machinery.

Tompkins County poised for manufacturing boom with Menlo Micro and Micron investments “Menlo Micro announced a significant investment of over $50 million to establish a fabrication facility in Lansing, near Ithaca, New York, signaling a major boost for the local manufacturing workforce.” Read more Plug Power wins $75 million grant from DOE “The Latham hydrogen … NYS Manufacturing and Tech News 3.11.24 Read More »

Posted by on 2024-03-15

We continue our blog series on the great work of our New York State assets in Advanced Materials across the state. This week, we feature the work of Rensselaer Polytechnic Institute (RPI) in Troy, NY, and their work on next generation building technology with an aim to decarbonize the built environment. This includes working with … Advanced Materials Strengths and Assets in NYS: Focus on Rensselaer Polytechnic Institute Read More »

Posted by on 2024-02-28

Embark on an enlightening exploration of New York’s economic transformation with special guest Alyson Slack from MRB Group, as we uncover the past and present of the state’s manufacturing sector. Together with FuzeHub’s Steve Melito we chart the course from a robust production history to a burgeoning service-oriented economy, all while acknowledging manufacturing’s lasting contributions … Podcast: Building Better Economies Read More »

Posted by on 2024-03-18

New $25M beauty manufacturing and innovation hub for Black- and women-owned businesses coming to Brooklyn Navy Yard “The Brooklyn Navy Yard is set to be home to a new $25 million state-of-the-art manufacturing, incubator, and accelerator facility focused on helping Black- and women-owned health and beauty businesses launch and grow in New York City.” Read … NYS Manufacturing and Tech News 3.4.24 Read More »

Posted by on 2024-03-08

In our third feature in our New York State Assets blog series on Advanced Materials, we focus on the groundbreaking work at the University at Buffalo. Their Department of Materials Design and Innovation focuses on accelerating lab discoveries into practical engineering applications. They are pioneering new approaches in material science education and research, leveraging technologies … Advanced Materials Strengths and Assets in NYS: Focus on University at Buffalo Read More »

Posted by on 2024-03-06

Signs that indicate manufacturing equipment is in need of repair include unusual noises, vibrations, leaks, decreased output, frequent breakdowns, and error messages. It is important to address these issues promptly to prevent further damage and avoid costly repairs or replacements.

When looking for a manufacturing equipment repair service provider, it is essential to consider certifications and qualifications. Look for technicians who are certified by the equipment manufacturer or have relevant training and experience in repairing specific types of machinery. This ensures that the repairs are done correctly and efficiently.

The time it takes to repair manufacturing equipment varies depending on the extent of the damage, availability of parts, and the complexity of the machinery. Minor repairs can be completed within a few hours to a day, while major overhauls may take several days or even weeks. It is important to work with a repair service provider who can provide a realistic timeline for the repairs.

Regular maintenance and repair of manufacturing equipment offer several benefits, including increased equipment lifespan, improved efficiency, reduced downtime, and lower operating costs. By addressing issues early on and keeping equipment in optimal condition, businesses can avoid costly repairs and replacements, as well as maintain a competitive edge in the market.

Manufacturing equipment repair services can be customized to fit specific industry needs by offering tailored maintenance plans, emergency repair services, on-site support, and preventive maintenance programs. Providers can work closely with businesses to understand their unique requirements and develop a comprehensive repair and maintenance strategy to keep equipment running smoothly and efficiently. This customization ensures that equipment downtime is minimized, production is maximized, and overall operational efficiency is improved.

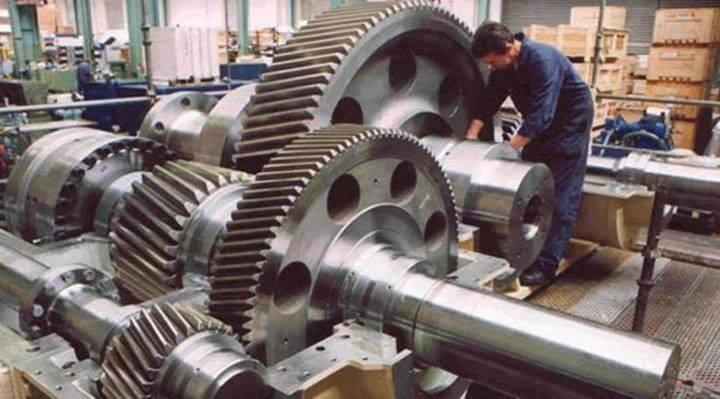

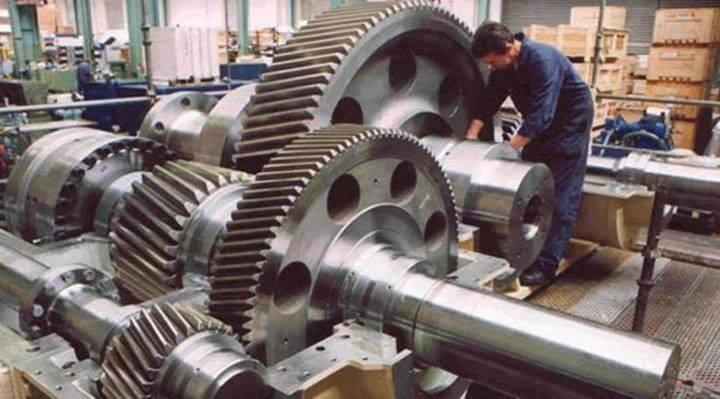

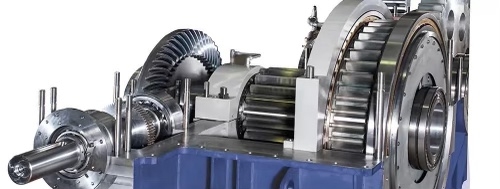

Gear cutting equipment with specialized configurations can be repaired by skilled technicians who have expertise in working with precision machinery, such as hobbing machines, gear shapers, and gear grinders. These technicians are trained to diagnose and troubleshoot issues related to gear cutting, including gear tooth profile errors, pitch errors, and surface finish problems. They are also familiar with the various types of gear cutting processes, such as hobbing, shaping, milling, and grinding, and can make adjustments to ensure that the equipment is operating at optimal performance. Additionally, these technicians have knowledge of gear materials, heat treatment processes, and lubrication requirements to ensure that the repaired equipment meets the necessary specifications for the intended application.

Diagnosing issues with industrial shredding machines involves a thorough inspection of various components such as blades, motors, belts, and sensors. Technicians may use diagnostic tools like multimeters, thermal imaging cameras, and vibration analyzers to pinpoint the source of the problem. Common issues that may arise include dull or damaged blades, overheating motors, loose belts, and malfunctioning sensors. By conducting regular maintenance checks and monitoring performance metrics, technicians can identify potential issues before they escalate into major problems. Additionally, analyzing data from the shredding process, such as throughput rates and energy consumption, can provide valuable insights into the machine's overall health and efficiency. Troubleshooting techniques may include adjusting blade settings, replacing worn parts, recalibrating sensors, and lubricating moving components. Ultimately, a systematic approach to diagnosing and addressing issues with industrial shredding machines is essential to ensure optimal performance and prevent costly downtime.

When it comes to handling repairs for industrial robotics used in cleanroom environments, it is crucial to follow strict protocols to maintain the integrity of the controlled environment. Technicians must be trained in cleanroom procedures and wear appropriate protective gear to prevent contamination. Repairs should be conducted using specialized tools and equipment designed for cleanroom use to avoid introducing particles or contaminants. Regular maintenance and calibration of the robotics equipment are essential to ensure optimal performance and prevent breakdowns. Additionally, documentation of all repairs and maintenance activities should be kept to track the history of the equipment and identify any recurring issues. Overall, a systematic approach to repairs in cleanroom environments is necessary to uphold the standards of cleanliness and efficiency required in such controlled settings.

Yes, our company offers specialized repairs for a wide range of industrial water treatment systems, including reverse osmosis systems, ultraviolet disinfection systems, ion exchange systems, and chemical dosing systems. Our team of experienced technicians is trained to handle complex repairs and maintenance tasks, ensuring that your water treatment system operates at peak efficiency. We use advanced diagnostic tools and techniques to identify and address issues quickly and effectively, minimizing downtime and maximizing system performance. Whether you need repairs for a specific component or a comprehensive system overhaul, our experts have the knowledge and skills to get the job done right. Contact us today to learn more about our industrial water treatment system repair services.